Colloidal Alumina's Rise in Semiconductor Polishing and Coatings Marks a Niche Shift in Market Dynamics, FMI Study

Uncommon applications of colloidal alumina in advanced coatings and semiconductor CMP are reshaping market opportunities and regional innovation.

NEWARK, DE, UNITED STATES, May 9, 2025 /EINPresswire.com/ -- While colloidal alumina is often associated with conventional roles such as abrasives and catalysts, a quieter yet more significant shift is happening in highly specialized sectors. The rising focus on high-purity processing, environmental resilience, and microelectronics is fueling demand for colloidal alumina in two notably underexplored areas: advanced coatings and chemical mechanical polishing (CMP) in semiconductors. These emerging uses are not only reshaping the perception of colloidal alumina but also redefining its value in high-tech industries where precision and performance are paramount.

This article explores the niche yet fast-evolving landscape of colloidal alumina applications, supported by fact-based trends and examples from real-world market dynamics. It uncovers why this overlooked segment might soon emerge as a critical driver in the broader high-purity alumina sol market.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/REP-GB-13207

𝐄𝐦𝐞𝐫𝐠𝐢𝐧𝐠 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐢𝐧 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬

The use of colloidal alumina in coatings is gaining attention in sectors that demand superior thermal resistance, hardness, and transparency without compromising environmental compliance. Colloidal alumina coatings offer a nanostructured architecture, enabling superior film formation on metallic, polymeric, and glass substrates. These properties make it particularly effective in high-temperature and corrosion-resistant environments.

One of the more uncommon yet impactful uses of colloidal alumina is in anti-scratch coatings for automotive displays and optical-grade panels. Japanese and German automakers have been quietly integrating alumina-based nanoscale coatings in infotainment systems and HUDs (heads-up displays), leveraging their ability to provide scratch resistance while maintaining optical clarity. Unlike traditional silica coatings, colloidal alumina can withstand higher thermal cycles and offers better chemical bonding with the substrate due to its positively charged surface.

Additionally, in the aerospace and defense sector, alumina sol coatings are being evaluated for their role in protecting carbon composites and ceramic components exposed to intense mechanical and thermal stress. These thin, lightweight coatings are not only reducing component wear but also extending the operational life of expensive assemblies. The growing interest in using colloidal alumina coatings for advanced material protection in satellites and UAVs underlines the material's versatility beyond its traditional industrial profile.

𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐑𝐨𝐥𝐞 𝐢𝐧 𝐒𝐞𝐦𝐢𝐜𝐨𝐧𝐝𝐮𝐜𝐭𝐨𝐫 𝐂𝐌𝐏 (𝐂𝐡𝐞𝐦𝐢𝐜𝐚𝐥 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐏𝐨𝐥𝐢𝐬𝐡𝐢𝐧𝐠)

In semiconductor manufacturing, the role of colloidal alumina is quietly expanding within CMP slurry formulations, particularly for planarizing tungsten and barrier layers. As semiconductor nodes move below 5nm, achieving atomic-level smoothness without inducing defects becomes critical. While silica-based slurries remain dominant, manufacturers are increasingly incorporating alumina nanoparticles due to their controlled hardness, tunable zeta potential, and minimal agglomeration.

Colloidal alumina exhibits a unique advantage when used in low-pressure CMP applications, reducing dishing and erosion during wafer surface planarization. Its ability to deliver high selectivity and low defectivity makes it ideal for advanced logic and memory chips. For instance, South Korean chipmakers have been exploring alumina-enhanced CMP formulations for their DRAM and NAND flash processes, reporting improved surface uniformity and reduced defect counts during yield analysis.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/colloidal-alumina-market

What differentiates colloidal alumina from traditional alumina abrasives is its particle size and suspension stability. While regular alumina abrasives are prone to settling and surface scratching, colloidal alumina remains uniformly suspended and delivers controlled polishing action at the nano level. This not only boosts performance in advanced CMP but also aligns with green manufacturing initiatives due to reduced slurry consumption and wastewater treatment loads.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 𝐇𝐮𝐛𝐬 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧

Although global interest in colloidal alumina is rising, regional innovation hubs are playing a disproportionate role in accelerating its niche applications. Japan continues to lead in producing ultra-high-purity colloidal alumina for electronics, driven by its domestic semiconductor and optical component industries. Japanese companies like Nissan Chemical and Showa Denko have invested heavily in customizing colloidal alumina dispersions for end-use in electronics, particularly where purity levels exceed 99.99%.

Meanwhile, China’s Guangdong and Jiangsu provinces are experiencing growth in alumina sol coating formulations tailored for photovoltaic glass and flexible electronics. Several start-ups in Shenzhen and Suzhou are experimenting with hybrid sol-gel coatings using colloidal alumina to enhance UV resistance and self-cleaning capabilities in solar panels. These solutions not only improve panel efficiency but also reduce maintenance costs in utility-scale solar farms.

In the USA, academic and private sector collaborations are advancing the use of alumina-based nanoparticle formulations for CMP slurry recycling—an initiative that could dramatically lower slurry-related operational costs in fabs. These developments point toward a deeper integration of colloidal alumina in process optimization strategies beyond material supply.

𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤 𝐚𝐧𝐝 𝐈𝐧𝐯𝐞𝐬𝐭𝐦𝐞𝐧𝐭 𝐒𝐢𝐠𝐧𝐚𝐥𝐬

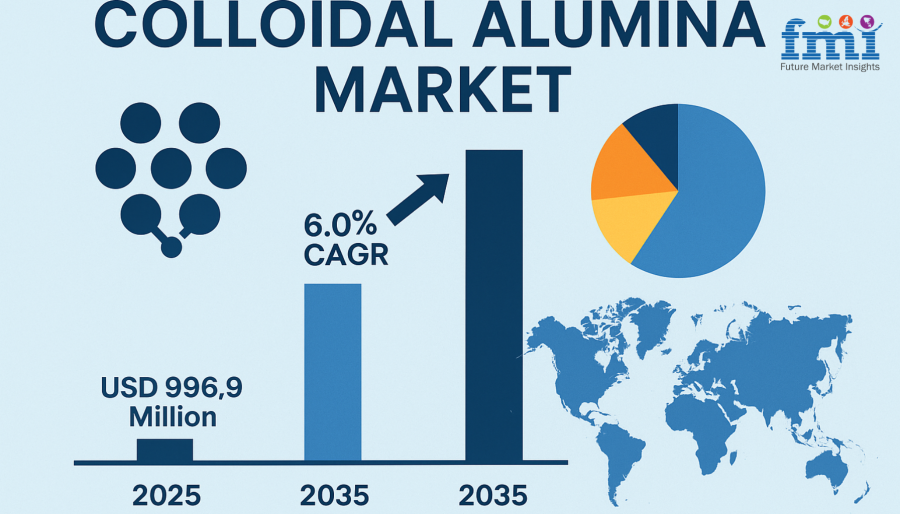

The colloidal alumina market is entering a phase where niche uses could soon become central growth pillars. As industries such as semiconductors, aerospace, and automotive electronics place greater emphasis on precision and durability, the need for tailored, high-performance nanomaterials is set to rise. The market for colloidal alumina is projected to grow at a CAGR exceeding 6.0% through 2035, with much of this growth concentrated in specialty applications rather than traditional abrasive or catalyst segments.

Environmental benefits are also contributing to colloidal alumina’s rise. Compared to other polishing agents and coating additives, it requires fewer chemical stabilizers, offers higher yield during processing, and can be recovered or reused in closed-loop systems, answering the frequently asked query around its sustainability.

𝐆𝐞𝐧𝐞𝐫𝐚𝐥 & 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

While the market remains relatively fragmented, increasing collaboration between chemical manufacturers and application-specific industries suggests a convergence that may trigger accelerated standardization and volume adoption. Investment in production technologies, such as hydrothermal synthesis and spray-drying for uniform dispersion, will also be crucial for commercial scalability.

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐬 𝐨𝐟 𝐂𝐨𝐥𝐥𝐨𝐢𝐝𝐚𝐥 𝐀𝐥𝐮𝐦𝐢𝐧𝐚 𝐌𝐚𝐫𝐤𝐞𝐭

By Application:

- Catalysts

- Refractories

- Aluminosilicate Fiber

- Others

By Type:

- Under 20 nm

- 20-50 nm

- 50-100 nm

- Above 100 nm

By End-use Industry:

- Textile

- Ceramic and Refractory

- Inorganic Fiber

- Others

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

USA and Canada Copper Market: https://www.futuremarketinsights.com/reports/usa-and-canada-copper-market

Aluminum Chemicals Market: https://www.futuremarketinsights.com/reports/aluminum-chemicals-market

Europe Silica Sand for Glass Making Market: https://www.futuremarketinsights.com/reports/europe-silica-sand-market

USA and Canada Alumina Market: https://www.futuremarketinsights.com/reports/united-states-and-canada-alumina-market

United Kingdom Veneered Panels Market: https://www.futuremarketinsights.com/reports/united-kingdom-veneered-panels-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release