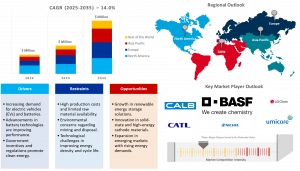

Cathode Materials Market Hits USD 29.85 Billion in 2024, Set for 14% CAGR Through 2035

Cathode Materials Market was valued at USD 29.85 Billion in 2024 and is projected to grow at a CAGR of 14.0% during the forecast period (2025-2035).

INDORE, INDIA, April 29, 2025 /EINPresswire.com/ -- The market for cathode materials has been gaining robust momentum in recent years with an increasing need for high-performance energy storage. The materials are employed in a range of battery technologies such as lithium-ion batteries used in electric vehicles (EVs) and portable gadgets. As the global economy is transforming to renewable sources of energy and electric cars, the need for high-performance cathode materials is increasing exponentially. Cathode materials are primarily developed from compounds such as lithium cobalt oxide (LCO), lithium iron phosphate (LFP), and nickel manganese cobalt (NMC). These are selected for efficient storage and release of energy such that the overall performance, energy density, and life of the battery are maximized. Of these, NMC is one of the most widely used materials because of its well-balanced properties that can be exploited for EV batteries. One of the most significant drivers for the rise in the market for cathode materials is the use of electric vehicles. As various governments and companies globally pledge to lower carbon emissions, EVs are emerging as the first point of explanation. The need for cathode materials with the ability to handle higher energy output is likely to increase, thereby enhancing market growth.Click To get a Sample PDF (Including Full TOC, Graphs & Charts, Table & Figures) @

https://www.omrglobal.com/request-sample/cathode-material-market

Market Trends

Transition to NMC and NCA Chemistries with High Nickel

The cathode materials market globally has been experiencing dramatic changes with the growing need for more performance-oriented lithium-ion batteries. One of the trends underlying this change is the increasing preference for high-nickel cathode chemistries, including NCM (Nickel Cobalt Manganese) and NCA (Nickel Cobalt Aluminum). Nickel-based chemistries, such as NMC and NCA, were dominant in the electric car battery market in 2021 with 75% of cathode material demand share due to their advantages for driving range. They contain higher energy densities, which are essential to meeting the evolving requirements of electric vehicles (EVs) and other future-generation energy storage systems. The transition towards high-nickel compositions is not just for improved battery performance but also to reduce dependence on cobalt, a metal plagued by supply chain shortages and ethics of sourcing. The transition to high-nickel NMC and NCA chemistries is accompanied by cost reduction and increased sustainability.

Producers are increasingly exploring various methods of purifying nickel and other critical materials to reduce production costs and mitigate the adverse impacts on the environment. To address the specific needs of new batteries, continuous research and development activities are also accelerating the development of novel cathode materials, including new, more stable, and more efficient compositions. This shift in material chemistry is also shaping the competitive forces of the market for cathode materials. Companies will be well placed to corner the emerging market for electric vehicles and renewable energy applications if they can access sources of high-purity nickel and develop successful manufacturing methods. Increased emphasis on high-nickel chemistries is likely to push more battery technology development in the direction of stronger, high-performance energy storage systems.

Rapid Increase in LFP (Lithium Iron Phosphate) in Energy Storage and EVs

The energy storage and electric vehicle (EV) sector is driving the growth in the cathode materials market rapidly, primarily as the use of lithium iron phosphate (LFP) is increasing in these industries. Compared to other cathode materials such as Nickel Manganese Cobalt (NMC), LFP has emerged as the preferred material due to its higher temperature stability, longer lifespan, and reduced cost. LFP is now set to surge globally. Recently, major non-Chinese EV manufacturers, such as Tesla and Volkswagen, announced moves to LFP chemistries for entry-level high-volume EV models. Almost half of all Tesla EVs produced in the first quarter of 2022 used LFP. LFP battery production is now planned in Europe and the United States to meet anticipated LFP demand for EVs in these regions. The expansion of LFP-based batteries has also been driven by increasing demand for cheap and environmentally friendly energy storage solutions. This boom is also being spurred by the global shift towards renewable energy and the growth of the electric vehicle (EV) market, as governments globally invest in green mobility and clean energy infrastructure.

Further, innovations in LFP chemistry and battery technology are driving energy density innovation, enabling LFP to grow increasingly competitive with other cathode materials. As high-performance energy storage material demand expands, the demand for cathode materials is expected to remain on a positive growth trend. The trend towards LFP not only revolutionizes the EV industry but also impacts the overall energy storage market as its safety and affordability advantages are better appreciated. In addition, long-term projections forecast a sharp decline in cobalt and nickel reliance, in favor of cleaner, more abundant inputs like LFP.

Order Your Report Now For A Swift Delivery

Regional Outlook

Strong Presence of Key Market Players in Asia-Pacific

Asia Pacific's enormous surge in demand for cathode material is largely attributed to the growing battery production industry. China, Japan, and South Korea are the leading countries, with their enormous capacity for production and well-established supply chains. Globally, LFP battery production is concentrated in China, which accounts for just over one-third of total LFP cell manufacturing. NMC (nickel manganese cobalt) battery cell production in China represents slightly more than a quarter of the country's total battery output. By 2030, China is expected to produce about 25% of the world’s NMC cathode materials.

Europe Holds Major Market Share

The demand for cathode materials in Europe has increased owing to the transition towards cleaner forms of energy. With the increasing electric mobility, the demand for lithium-ion batteries has also surged immensely. Cathode materials such as NMC and LFP are gaining popularity owing to their efficiency and stability. Europe’s battery cell production is set to be dominated by NMC chemistry by 2030. Over the next decade, the region’s share in global NMC battery production will become increasingly significant. At the same time, LFP cell production in Europe is expected to grow steadily, gradually becoming more relevant in the market.

Market Segmentation and Growth Areas

Lithium-Ion Segment is Expected to Dominate the Market, Holding the Largest Share

The cathode material market has experienced spectacular growth in recent years driven predominantly by increasing demand for lithium-ion batteries across industries. The rapid expansion of electric cars and renewable energy storage systems has generated a robust demand for high-performance, efficient battery materials. Companies looking to enhance energy density and battery longevity with novel cathode chemistries are strategically beneficial. NMC (Nickel Manganese Cobalt) and LFP (Lithium Iron Phosphate) materials are increasingly popular in use due to their stability and performance-driven properties. Government policies favoring green energy and green mobility favor the industry's growth as well.

The Automotive Segment is Expected to Capture a Significant Share of the Market

The market for premium cathode materials has been significantly impacted by the automotive industry's shift to electrification. Manufacturers are investing heavily in battery technology as electric cars (EVs) continue to gain traction globally. The use of cathode materials, which are essential components of lithium-ion batteries, has increased dramatically. Companies are looking into alternatives such as NMC (nickel manganese cobalt) and LFP (lithium iron phosphate) to meet performance, cost, and safety needs. This increasing adoption is not confined to passenger cars, commercial fleets are also shifting towards electric variants, further fueling market demand. Supply chains are being reorganized to provide a consistent supply of critical raw materials such as nickel, cobalt, and lithium. Regulatory imperatives driving zero-emission mobility in Europe, North America, and Asia Pacific are contributing to the trend.

Market Limitations and Challenges

•Technical compatibility and complex integration: It is not easy to integrate cathode materials into existing battery manufacturing processes and equipment. The changes in the material properties may involve the redesign of cells, equipment, and quality control systems, which may be costly and time-consuming.

•High Capital Outlay: The development, manufacturing, and deployment of advanced cathode materials such as NMC, LFP, or solid-state types require substantial capital expenditure. The expenditure entails the acquisition of high-purity raw materials, upgrading production lines, and adherence to very strict regulation standards. For small and mid-tier producers or plants in emerging markets, such a capital requirement can act as a primary entry barrier.

Request for Customization: https://www.omrglobal.com/report-customization/cathode-material-market

Market Players Outlook

The major companies operating in the global cathode materials market include China Aviation Lithium Battery (CALB), Contemporary Amperex Technology Co. (CATL), BASF SE, LG Chem, Ltd., NICHIA CORP., NEI Corp., Sumitomo Metal Mining Co., Ltd. and Umicore among others. Market players are leveraging partnerships, collaborations, mergers, and acquisition strategies for business expansion and innovative product development to maintain their market positioning. Cathode materials are widely categorized into types such as NCM, NCA, NCMA, and LFP based on their composition. LG Chem plans to expand its production capacity to 360,000 tons per year, focusing on facilities in South Korea and the US by 2030, to meet growing customer demand. LG Chem produces cathode materials at its plants in Cheongju and Gumi, South Korea, as well as a new plant in Clarksville, Tennessee, USA.

Recent Developments

•In March 2025, LG Chem showcased its LG Precursor Free (LPF) cathode materials at Interbattery 2025, at COEX in Seoul, South Korea. LG Chem will be the first Korean company to begin mass production of precursor-free cathode materials, enhancing its presence in the battery materials market. Interbattery is Korea’s largest battery industry exhibition, with participation expected from over 640 companies worldwide in a space exceeding 400,000 square meters. Starting mass production of LPF cathode materials in the first half of this year, LG Chem plans to expand LPF technology applications across new products, providing customers with differentiated, customized solutions in performance, cost, and environmental sustainability.

•In September 2024, LG Chem announced it had secured a supply of cathode active materials (CAM) for Prime Planet Energy & Solutions (PPES), a Japanese joint venture of Toyota Motor Corporation and Panasonic Corporation. PPES, a pivotal EV battery manufacturer based in Japan, has been supplying batteries to numerous global OEMs including Toyota. As part of its global expansion, LG Chem will join forces with PPES’s EV battery strategy. Targeting to start in 2026, LG Chem will supply CAM to the PPES plant in Japan.

•In June 2024, Ascend Elements has just shipped decarbonized cathode materials to Freudenberg e-Power Systems for heavy-duty applications. Recycled battery metal cathode materials can allow EV battery manufacturers to be eligible for US tax credits under the Inflation Reduction Act (IRA). Ascend Elements uses a patented process known as Hydro-to-Cathode® direct precursor synthesis to manufacture NMC pCAM and CAM from used lithium-ion batteries and battery manufacturing scrap.

•In February 2024, LG Chem announced a supply of more than 500,000 tons of cathode materials, enough for approximately 5 million units of Electric vehicle (EV) production to General Motors. A long-term supply contract to commence from 2026 through 2035 with the start of production of the cathode manufacturing plant in Tennessee, U.S., establishing a local supply chain optimized for North American EVs.

Some of the Key Companies in the Cathode Materials Market Include-

• ALEEES

• Altmin Pvt. Ltd.

• American Elements

• Ascend Elements, Inc.

• B&M Science And Technology

• BASF SE

• China Aviation Lithium Battery (CALB)

• Contemporary Amperex Technology Co. (CATL)

• Ecopro Co., Ltd.

• Epsilon Advanced Materials Pvt. Ltd.

• Finnish Minerals Group

• Ganfeng Lithium Group Co., Ltd

• Guizhou Zhenhua New Materials

• Huayou Cobalt Co., Ltd.

• Hunan Changyuan Lithium Technology Co., Ltd.

• L&F Corp.

• LG Chem Ltd.

• Nantong Ruixiang New Materials Co., Ltd.

• Nei Corp.

• Nichia Corp.

• Ningbo Shanshan

• Panasonic.

• Posco Future M Co., Ltd.

• Redwood Materials, Inc.

• Samsung SDI

• Shanshan Co.

• Shenzhen Dynanonic Co., Ltd.

• SK ON

• Sumitomo Metal Mining Co., Ltd.

• Tanaka Chemical Corp.

• Targray Technology International Inc.

• Texpower EV Technologies, Inc.

• Tianqi Lithium Co., Ltd.

• Toda Kogyo Corp.

• Umicore

• Xiamen Acey New Energy Technology Co., Ltd.

• Xiamen Tmax Battery Equipments Ltd.

Cathode Materials Market Segmentation Analysis

Global Cathode Materials Market by Material

• NMC Cathode Materials

• Lithium Cathode Materials

o Lithium Phosphate (LFP)

o Lithium Cobalt Oxide (LCO)

o Lithium Nickel Manganese Cobalt (NMC)

o Lithium Nickel Cobalt Aluminum (NCA)

o Lithium Manganese Oxide (LMO)

• Lithium Dioxide Cathode Materials

• Other Cathode Materials (Lithium Sulfur, Sodium Cobalt Oxide)

Global Cathode Materials Market by Battery Type

• Lithium-ion

• Lead Acid

• Nickel Cadmium

• Others

Global Cathode Materials Market by End-User

• Automotive

• Consumer Electronics

• Energy & Power

• Healthcare

• Industrial

Regional Analysis

• North America

o United States

o Canada

• Europe

o UK

o Germany

o Italy

o Spain

o France

o Rest of Europe

• Asia-Pacific

o China

o India

o Japan

o South Korea

o ASEAN Economies (Singapore, Thailand, Vietnam, Indonesia, and Other)

o Australia and New Zealand

o Rest of Asia-Pacific

• Rest of the World

o Latin America

o Middle East and Africa

Inquiry Before Buying: https://www.omrglobal.com/inquiry-before-buying/cathode-material-market

Anurag Tiwari

Orion Market Research Pvt Ltd

+ +91 91798 28694

email us here

Visit us on social media:

LinkedIn

Facebook

X

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release